When you select between 12V and 24V for a planetary gear motor in medical pumps, you make a decision that affects performance and safety. INEED brings years of expertise in designing motors for medical devices. You need to consider voltage for efficiency, reliability, and compliance with medical standards. INEED ensures you get high-quality, customized gear motors that fit your specific pump requirements.

Key Takeaways

- Choose the right voltage for your medical pump to ensure optimal performance and safety.

- Select a 24V motor for high torque and speed needs, especially for larger or stationary pumps.

- Opt for a 12V motor in portable devices to enhance efficiency and reduce noise.

- Consider customization options from INEED to meet specific pump requirements and improve functionality.

- Always check for compliance with medical standards to ensure safety and reliability in your devices.

Voltage and Pump Performance with INEED Planetary Gear Motor

12V DC Motor vs 24V DC Motor: Torque and Speed

You face an important choice when selecting a planetary gear motor for a medical pump. The 12v dc motor and the 24v dc motor each offer unique benefits. The 12v dc motor works well in applications where you need moderate speed and torque. The 24v dc motor delivers higher speed and torque, which is essential for pumps that must move fluids quickly or handle thicker substances.

- Voltage selection is critical for determining motor performance in medical applications.

- Higher voltages enable greater power output, essential for high torque and speed requirements.

- Lower voltages may be adequate for less demanding applications, impacting overall efficiency.

You should match the planetary gear motor to your pump’s needs. If your design requires more speed or torque, the 24v dc motor will provide the extra power. If your application is less demanding, the 12v dc motor can offer reliable performance with lower energy use.

Efficiency and Heat in Medical Pump Applications

Efficiency matters in every medical pump. The 12v dc motor and the 24v dc motor have different efficiency levels. You can see the comparison in the table below:

| Parameter | 12V | 24V |

|---|---|---|

| Efficiency | 33% | 47% |

| Current (A) | 0.72 | 0.858 |

| Torque (N.m) | 0.6 | 0.9 |

The 24v dc motor operates with higher efficiency. This means less energy turns into heat, which helps keep the planetary gear motor cool during long use. You reduce the risk of overheating in your medical pump by choosing the right voltage. The 12v dc motor may generate more heat if you push it to deliver high speed or torque.

Noise, Vibration, and Reliability

You want your medical pump to run quietly and reliably. The planetary gear motor from INEED uses advanced design to minimize noise and vibration. The 12v dc motor often produces less noise at lower speeds. The 24v dc motor can maintain smooth operation even at higher speed levels. Both options offer stable performance, but you should consider the working environment. If your pump runs in a sensitive area, the 12v dc motor may be the best choice for quiet operation. For pumps that need consistent speed and torque, the 24v dc motor provides reliable results. INEED ensures every gear motor meets strict standards for reliability, so you can trust your medical device to perform as needed.

Select Between 12V and 24V for Medical Pump Needs

Application Scenarios for 12V DC Motor

You often need to select between 12v and 24v when designing portable or compact medical pumps. The 12v dc motor fits best in devices where size, weight, and energy efficiency matter most. You see this motor in many battery-powered or mobile medical devices. The 12v electric motor allows you to create lightweight and easy-to-carry equipment. You can use the 12v dc motor in applications that require precise control and low noise.

Here are common medical pump applications that use the 12v dc motor:

| Application | Description |

|---|---|

| Infusion Pumps | Provide controlled drug delivery, adjustable by medical staff. |

| Ventilators | Offer assisted breathing, especially in emergency and portable setups. |

| Portable Dialysis Machines | Facilitate home-based kidney dialysis treatments. |

You benefit from several performance advantages when you select between 12v and 24v and choose the 12v dc motor for these pumps. The 12v dc motor offers high efficiency, which means you get more mechanical energy from the same amount of electrical energy. This reduces power consumption and extends battery life. The compact size of the 12v dc motor lets you design smaller pumps with high power density. You can achieve precise speed control using PWM, which helps you tune the rpm and reduce noise. The 12v dc motor also operates quietly, which is important for patient comfort.

| Advantage | Description |

|---|---|

| Efficiency | 12v dc motors convert more electrical energy into mechanical energy, reducing power consumption. |

| Compact Size | 12v pumps allow for smaller, lighter equipment with high power density. |

| Control Precision | You can control 12v pumps precisely, adjusting speed and rpm for optimal performance. |

| Low Noise | 12v dc motors minimize mechanical resonance and vibration, keeping operation quiet. |

You should select between 12v and 24v based on your need for portability, quiet operation, and precise control. The 12v dc motor works well for pumps that must run on batteries or fit into small spaces.

When to Choose 24V DC Motor for Pumps

You may need to select between 12v and 24v for larger or stationary medical pumps. The 24v dc motor gives you higher torque and speed, which is important for pumps that move large volumes or handle thicker fluids. You get more high torque output and better motor performance with the 24v dc motor in these cases.

The 24v dc motor offers several benefits for stationary medical pump systems:

| Benefit | Description |

|---|---|

| Low-voltage operation | Reduces electrical hazards, making the pump safer for medical use. |

| High torque density | Delivers efficient performance, supporting high torque output for demanding applications. |

| Long service life | Brushless design means no mechanical brush wear, so you get more reliability and less downtime. |

| Precise speed and motion control | Lets you control speed and rpm accurately, which is essential for medical pump functionality. |

| Low noise and vibration | Keeps operation quiet, which is important in medical environments. |

You should select between 12v and 24v by considering the power and torque needs of your pump. The 24v dc motor is ideal for applications that require continuous operation, high rpm, and high torque output. You can use the 24v dc motor in pumps that must run for long periods without maintenance.

INEED Customization and Integration Options

You can select between 12v and 24v and still get a motor that fits your exact needs. INEED offers a wide range of customization options for planetary gear motors in medical pumps. You can choose custom shaft designs, such as D-cut, flatted, or threaded shafts. You can select special gear materials, including metal or reinforced polymers, to match your application. You can add encoders or feedback options to monitor speed and rpm in real time.

| Customization Option | Description |

|---|---|

| Custom Shaft Designs | D-cut, flatted, and threaded options available. |

| Special Gear Materials | Choose from metal or reinforced polymers. |

| Encoder/Feedback Options | Add encoders for precise speed and rpm control. |

You can also select between 12v and 24v dc geared motors with different gear ratios to match your pump’s speed and torque requirements. INEED supports you with technical advice and free samples, so you can test motor selection before finalizing your design. You get reliable dc geared motors that meet your medical pump needs, whether you need high rpm, high torque output, or quiet operation.

Tip: When you select between 12v and 24v, always consider the specific requirements of your pump, such as size, power source, and desired motor performance. INEED can help you customize dc geared motors for any medical application.

Decision Factors for INEED Planetary Gear Motor in Pumps

Power, Safety, and Compliance

You must consider power and safety when you select a planetary gear motor for medical pumps. The rated voltage plays a key role in determining how much power your dc motor delivers. You can choose between 12v and 24v options based on your pump’s requirements. The 24v electric motor provides higher torque and speed, which is important for pumps that need to move fluids quickly. You also need to ensure compliance with medical standards. INEED planetary gear motors meet strict certifications for medical devices. Review the table below to see the most important certifications:

| Certification | Description |

|---|---|

| ISO 13485 | Quality management systems for medical devices |

| ISO 14971 | Risk management framework for medical devices |

| IEC 60601 | Electrical safety standards for medical devices |

| ISO 10993 | Biocompatibility and biological evaluation |

| IEC 62304 | Software lifecycle processes for medical devices |

| 21 CFR Part 820 | U.S. FDA quality system regulation |

| RoHS & REACH | Environmental and chemical safety compliance |

| IEC 62366 | Usability engineering for medical devices |

Battery Life and System Compatibility

You want your medical pump to run efficiently and reliably. The choice between 12v and 24v affects battery life and system compatibility. The 12v dc motor works well in portable pumps, helping you extend battery life. The 24v electric motor suits stationary pumps that need more power and longer operation. You must check system compatibility before you select a motor. Consider these factors:

- Torque output

- Speed and RPM

- Size and form factor

- Voltage and power requirements

- Noise and vibration levels

- Reliability and lifespan

- Precision and control

You should always match the rated voltage and connector type to your device’s electrical system. This prevents damage and ensures proper operation. The dc motor must deliver the right speed and torque for your pump’s needs.

Cost, Reliability, and Support

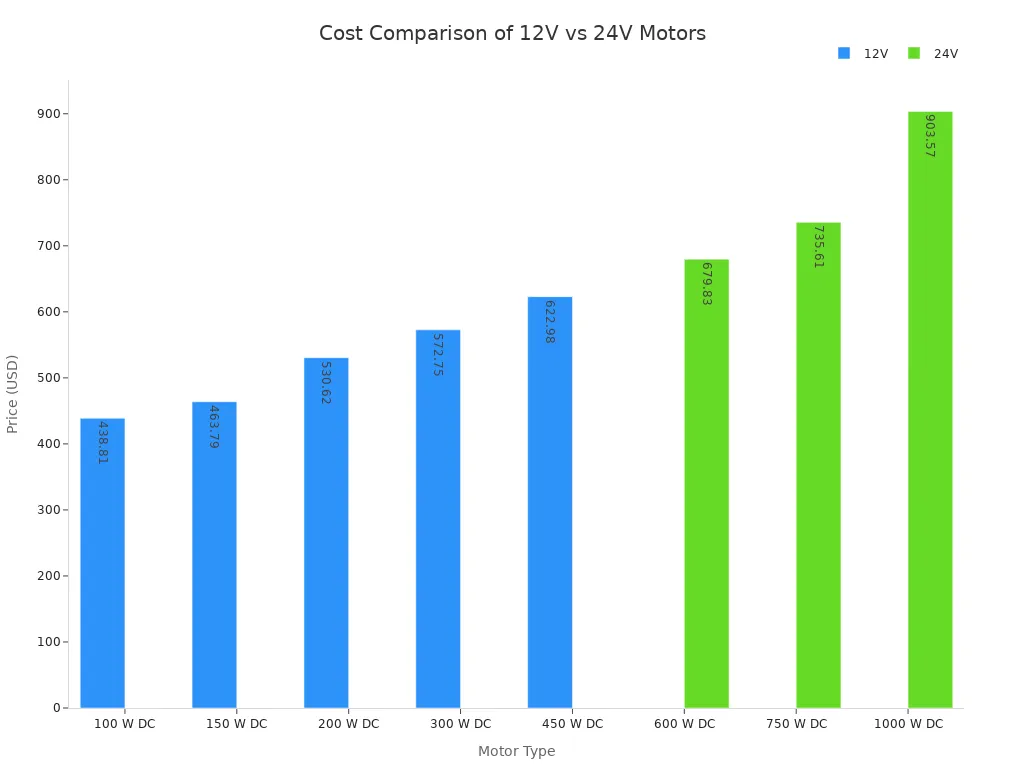

You need to balance cost and reliability when you choose between 12v and 24v planetary gear motors. The table below shows price differences for various motor types and voltages:

| Motor Type | Voltage | Price |

|---|---|---|

| 100 W DC | 12v | $438.81 |

| 150 W DC | 12v | $463.79 |

| 200 W DC | 12v | $530.62 |

| 300 W DC | 12v | $572.75 |

| 450 W DC | 12v | $622.98 |

| 600 W DC | 24v | $679.83 |

| 750 W DC | 24v | $735.61 |

| 1000 W DC | 24v | $903.57 |

You get reliable performance from both 12v and 24v dc motors. INEED supports you with technical advice and free samples. You can test different motor options to find the best fit for your medical pump. The 24v electric motor offers long service life and high speed, while the 12v dc motor provides cost-effective solutions for portable devices.

You need to match the voltage of your planetary gear motor to your medical pump’s requirements. INEED offers reliable, customizable solutions for both 12V and 24V systems. You can use these motors in infusion pumps, ventilators, and mobility equipment where precise control and high torque matter. For best results, follow these inspection steps:

| Aspect of Inspection | Benefit |

|---|---|

| Regular Checks for Wear and Tear | Prevents minor issues from escalating into catastrophic failures. |

| Identifying Potential Issues Early | Minimizes downtime and reduces repair costs significantly. |

You can contact INEED for technical support or request free samples to test in your application.

FAQ

What factors should you consider when choosing between 12V and 24V motors?

You should look at your pump’s power needs, size, and battery life. Check if your device requires high torque or speed. Review your system’s voltage compatibility and safety standards.

Can you use a 24V motor in a battery-powered medical device?

You can use a 24V motor, but you need a battery system that supports 24V. Higher voltage may increase weight and size. For portable devices, 12V motors often work better.

How does voltage affect noise and vibration in medical pumps?

Higher voltage motors, like 24V, usually run smoother at high speeds. Lower voltage motors, like 12V, often produce less noise at low speeds. Choose based on your pump’s speed and environment.

Tip: Test both voltages in your application to find the quietest and most stable option.

What are the main certifications for INEED planetary gear motors in medical pumps?

| Certification | Purpose |

|---|---|

| ISO 13485 | Medical device quality system |

| IEC 60601 | Electrical safety |

| RoHS & REACH | Environmental compliance |

You should always check for these certifications before selecting a motor.

See Also

Selecting The Ideal Planetary Gear Motor For Precision Screwdrivers

Choosing The Best Configuration For Battery Powered Electric Motors

How To Choose The Perfect 3 Volt DC Motor For Projects

Choosing The Appropriate Rotate Motor For Industrial Uses

Eight Essential Steps To Choose The Right ERM Vibrator Motor