Selecting the right motorized gearbox requires you to understand your project’s load, speed, and torque. You must match these with the correct motorized gearbox and motor specifications for reliable performance. Many factors affect your choice, including operating parameters, design, and critical properties. The table below shows some of the most common project requirements:

| Category | Factors |

|---|---|

| Operating Parameters | Speed, Torque, Temperature |

| Design Parameters | Gearbox Size, Material |

| Critical Properties | Efficiency, Stiffness |

You should consider compatibility and customization to avoid mistakes. INEED offers brushless gear motors that provide tailored solutions for different industries.

Key Takeaways

- Define your project needs by calculating load, torque, and speed requirements to avoid costly mistakes.

- Choose the right gearbox type (spur, planetary, or worm) based on efficiency, durability, and torque handling for your application.

- Consider the duty cycle of your motor and gearbox to ensure they can handle continuous or intermittent operation effectively.

- Always check compatibility between the motor and gearbox to ensure they fit together and perform well in your specific environment.

- Plan for future upgrades by selecting modular and customizable gearbox solutions that can adapt to changing project needs.

Define Project Needs for Motorized Gearbox

Before you select a gearbox, you need to define your application requirements. This step helps you match the right motorized gearbox to your project and avoid costly mistakes. You should focus on the main components of gearbox sizing: load, torque and speed requirements, and duty cycle.

Load and Torque Calculation

Start by identifying the load your application will handle. Load refers to the force that the gearbox must move or control. You should calculate torque, which is the force that causes rotation. There are three types of torque to consider:

- Starting torque: The force needed to begin moving the load from a standstill.

- Full-load torque: The force required to keep the load moving at the desired speed.

- Breakdown torque: The maximum force the motor can provide before it stalls.

You can use these formulas to calculate torque:

- Metric formula: Torque (Nm) = Power (kW) × 9550 / Speed (RPM)

- Imperial formula: Torque (lb-ft) = Power (hp) × 5252 / Speed (RPM)

Accurate measurement of force and distance from the center of rotation gives you the running torque for your application. The table below shows how load affects the lifespan of a gearbox:

| Condition | Impact on Lifespan |

|---|---|

| Excessive Load | Leads to premature mechanical failure due to increased stress on components. |

| Optimal Load | Recommended to operate at 60% to 80% of maximum rated capacity for longevity. |

Speed and Gear Ratio Selection

Speed is another critical factor in your application requirements. You must decide how fast you want the output shaft of the gearbox to rotate. The gear ratio determines how the gearbox changes speed and torque. Use these formulas to help with your selection:

| Formula | Description |

|---|---|

| Gear ratio = (Number of teeth on driven gear) ÷ (Number of teeth on driving gear) | Calculates the gear ratio for speed and torque adjustments. |

| Output torque = Input torque × Gear ratio | Shows how torque increases with gear ratio. |

| Output speed = Input speed ÷ Gear ratio | Determines the output speed based on gear ratio. |

Selecting the right gear ratio improves energy efficiency and reduces wear. Proper gear ratio choices minimize energy loss and heat, which helps your gearbox last longer.

Application and Duty Cycle

You must consider the duty cycle for your application. Duty cycle describes how often and how long the motor and gearbox run. Common duty cycles include:

- Continuous operation: The motor runs for long periods without stopping.

- Intermittent duty: The motor runs in short bursts with breaks in between.

Continuous operation can cause higher temperatures and more gear wear. Intermittent duty allows for cooling periods, which may let you use smaller motors. Duty cycle affects gear wear rates and temperature rise, so you need to match the gearbox to your application’s needs.

Tip: INEED provides technical support to help you calculate and match load, torque, speed, and duty cycle for your application. Their experts can guide you through the process and recommend the best gearbox for your project.

Select the Right Gearbox and Gear Motors

Choosing the right gearbox and motor for your project is a critical step in achieving reliable performance. You need to understand the differences between gearbox types, evaluate gear motors, and consider customization options. INEED offers brushless gear motors that work with various gearbox types, giving you flexibility for different applications.

Gearbox Types (Spur, Planetary, Worm)

You must know the main types of gearbox designs before you select the right gearbox for your project. Each type has unique features that affect sizing, torque, efficiency, and durability.

| Gear Type | Efficiency (%) | Durability | Torque Handling |

|---|---|---|---|

| Worm Gear | 30-60 | Less durable, prone to wear | Stalls at lower torque |

| Planetary Gear | High | High, versatile | Superior load handling |

| Spur Gear | Moderate | Durable, cost-effective | Similar to planetary under load |

Spur gearboxes are the most common in robotics and industrial settings. They use straight teeth to transfer power between parallel shafts. Spur gearboxes provide precise speed and torque control, making them suitable for many gear motor applications. Planetary gearboxes excel in load handling and efficiency. Worm gearboxes offer compact sizing but have lower efficiency and durability.

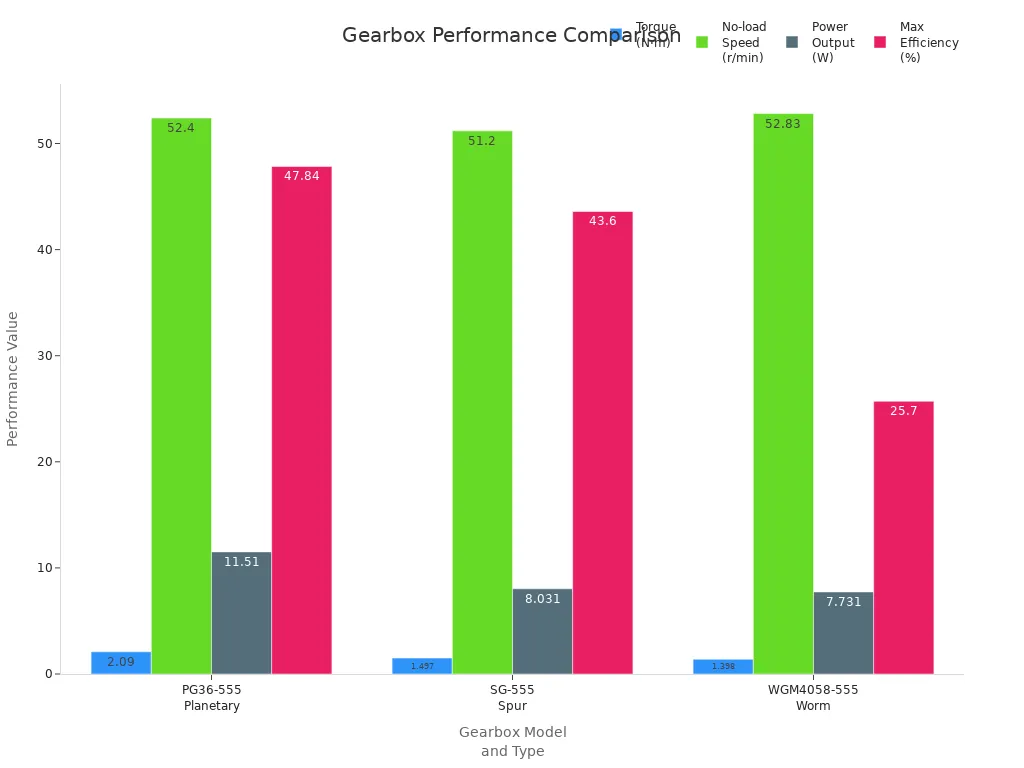

You can see the performance differences in the chart below:

When you select the right gearbox, consider the torque requirements, sizing constraints, and the type of gear that matches your application.

Gear Motors from INEED

INEED’s brushless gear motors combine advanced motor technology with high-quality gearboxes. These gear motors deliver high torque output, energy efficiency, and long service life. You can use them in applications that require precise control and reliable performance.

| Feature | Brushless Gear Motors | Brushed Gear Motors |

|---|---|---|

| Scope of Application | High control requirements, high speed | Power equipment, lower speed |

| Service Life | Tens of thousands of hours | About 1,000 hours, requires brush replacement |

| Use Effect | Strong controllability, variable speed | Constant speed, difficult speed adjustment |

| Energy Saving | More energy-efficient with inverter technology | Less energy-efficient due to brush friction |

| Maintenance | Virtually maintenance-free | Requires regular brush replacement |

INEED gear motors provide up to 15 Nm torque for demanding tasks. Their compact sizing, less than 42mm wide, fits tight spaces. The gearbox and motor combination enhances power usage and durability. You can rely on these gear motors for industrial, medical, and robotics projects. INEED gear motors minimize energy losses and reduce operational costs. You get a suitable gear motor for your specific needs.

Customization Options

You may need a customized gearbox and motor solution for your project. INEED offers a wide range of customization options to help you achieve the best sizing and performance.

| Customization Type | Options Available |

|---|---|

| Voltage | 3V-48V |

| Shaft Design | D-cut, keyway, hollow |

| Gear Materials | Metal, plastic |

You can request custom specifications for voltage, speed, and torque. INEED provides special output shafts, gear ratios, and encoders for position feedback. You can also choose unique packaging or branding for large orders. Customization allows you to match the gearbox and motor to your exact sizing and torque requirements.

Note: Customization may increase costs and lead times due to specialized materials and engineering. Complex designs and premium materials can raise production costs. INEED’s technical support team helps you manage these factors and ensures you get a suitable gear motor for your project.

When you select the right gearbox and gear motors, focus on sizing, torque, and application needs. INEED’s brushless gear motors and customization options give you the flexibility to build reliable and efficient solutions.

Ensure Compatibility and Performance

Selecting the right motorized gearbox means more than just matching torque and speed. You need to make sure the motor and gearbox fit together, deliver the correct output, and perform well in your environment. INEED’s strict quality control ensures every gearbox and gear motor combination meets high standards for output and reliability.

Motor and Gearbox Fit

You should always check that your motor and gearbox fit together both physically and electrically. Start by gathering all technical and commercial requirements for your project. Choose the right motor technology for your application. Pre-engineered solutions can help you avoid mismatches. Test the motor and gearbox together in conditions that match your real-world use.

| Issue Type | Description |

|---|---|

| Torque Mismatches | The motor’s peak torque must match the gearbox’s capacity to avoid system stress. |

| Feedback Handling | The drive must support the gearbox’s feedback needs, especially at high output speeds. |

| Wiring Issues | Non-standard wiring can cause connection problems between the motor and gearbox. |

Output RPM and Efficiency

You need to match the output speed of your gearbox to your application. Conveyor systems often use gearboxes with output speeds from 0.4 to 550 RPM, depending on the motor speed. The right output speed ensures your system runs smoothly and efficiently. Gearbox efficiency changes with load. Planetary gearboxes keep high efficiency even when the output load varies, because they share the output among several gears. This design reduces friction and keeps output performance stable.

| Motor Speed (RPM) | Output RPM Range |

|---|---|

| 1700 | 0.4 to 550 |

| 2500 | 0.4 to 550 |

| 3400 | 0.4 to 550 |

Tip: Always check the output speed and efficiency ratings before finalizing your gearbox choice.

Environmental and Mounting Factors

Your gearbox must perform well in its working environment. Material selection affects energy use and sustainability. Lubrication systems keep the output running smoothly and reduce pollution. Life Cycle Analysis helps you understand the total environmental impact of your gearbox.

Mounting options also matter. You can use mounting feet for a stable base, a flange on the output for direct attachment, or tapped holes for flexible mounting. In harsh environments, direct mounting inside a conveyor drum can protect the gearbox and reduce the need for extra lubrication.

| Mounting Option | Description |

|---|---|

| Mounting Feet | Provides a stable base for the gearbox, allowing for easy installation. |

| Flange on Output | Allows direct attachment to other components, reducing the need for additional parts. |

| Tapped Holes | Offers flexibility in mounting by allowing screws to be inserted on multiple sides. |

INEED’s quality control process checks every gearbox for fit, output, and reliability. You can trust that each output will meet your project’s needs, even in demanding environments.

Avoid Common Mistakes in Gearbox Selection

Choosing the right gearbox for your project can be challenging. Many people make mistakes that lead to higher costs, poor performance, or early failure. You can avoid these problems by learning about the most common errors and using the support and quality assurance that INEED provides.

Overlooking Specifications

You should always pay close attention to the specifications when selecting a gearbox. Ignoring important details can cause serious issues. Here are some frequent mistakes:

- Oversizing the gearbox for peace of mind can increase costs and make integration harder.

- Underestimating the real demands of your project may cause the gearbox to fail early.

- Disregarding environmental factors can reduce the gearbox’s performance and lifespan.

- Assuming plug-and-play integration can lead to compatibility problems.

- Choosing a gearbox based only on price can ignore the total cost over its lifetime.

INEED’s technical team can help you review your requirements and select the right gearbox for your needs.

Ignoring Maintenance Needs

Regular maintenance keeps your gearbox running smoothly and extends its life. If you skip maintenance, you risk unexpected breakdowns and higher costs. Good maintenance practices include:

- Performing the first oil change after 500 hours, then every 2,500 hours or 6 months.

- Checking oil levels and testing oil quality regularly.

- Using simple tests to check oil color, smell, and grit.

- Tracking inspections and comparing them to baseline measurements.

- Combining condition monitoring with scheduled checks to catch issues early.

Well-maintained gearboxes work more efficiently and last longer. INEED’s quality control and support make it easier for you to follow the right maintenance schedule.

Planning for Future Upgrades

You should think about future needs when choosing a gearbox. Consider changes in technology, demand, and the environment. Modular gearbox designs make upgrades and repairs easier.

“There is a growing trend toward modular and flexible designs in gearbox and motor engineering. Manufacturers are increasingly developing systems that can be easily adapted to different applications, allowing for greater customization and scalability.”

INEED offers customizable and modular gearbox solutions, so you can adapt your system as your project grows.

You can select the right motorized gearbox by following these steps:

- Define your requirements, including load and speed.

- Calculate torque and speed with a safety margin.

- Match the motor type to your application.

- Consider gearboxes and feedback systems.

- Test and adjust as needed.

| Benefit Type | Description |

|---|---|

| Customization & Modularity | Adaptable gearboxes allow easy upgrades and reduce redesign efforts. |

| Operational Benefits | Efficient gearboxes lower energy costs and improve reliability. |

Consult INEED for technical support and custom options. Double-check your calculations and plan for future needs to ensure a suitable and cost-effective solution.

FAQ

What factors should you consider when choosing a motorized gearbox?

You should look at load, speed, torque, duty cycle, and environment. Check if the gearbox fits your motor and application. Always review technical data and ask for expert advice if you feel unsure.

How do INEED brushless gear motors benefit your project?

INEED brushless gear motors give you high efficiency, long service life, and low maintenance. You can customize them for torque, speed, and voltage. These motors work well in robotics, medical devices, and industrial equipment.

Can you request custom gear ratios or shaft designs from INEED?

Yes, you can. INEED offers custom gear ratios, shaft shapes, and even encoder options. You can match the gearbox to your exact needs for better performance.

Tip: Customization helps you achieve the best fit for your project.

How do you maintain your gearbox for long-term reliability?

You should check oil levels, inspect for wear, and follow a regular maintenance schedule. Early oil changes and routine checks help prevent breakdowns.

| Maintenance Task | Frequency |

|---|---|

| First oil change | After 500 hours |

| Regular oil change | Every 2,500 hours |

| Visual inspection | Every 6 months |

See Also

Choosing the Ideal Vibrating Motor for Your Needs

Selecting a Planetary Gear Motor for Accurate Screwdriver Use

Finding the Best Rotate Motor for Industrial Use

Choosing the Perfect 3 Volt DC Motor for Projects

Selecting the Best Configuration for Battery Powered Electric Motors