Imagine you are building a robot and need precise, reliable motion. Using a gear motor 24vdc gives you strong torque and steady speed, which is perfect for robotics. You need to look at speed, torque, voltage, and how the motor fits your design. Many hobbyists face challenges like matching the 24v dc gear motor to the power supply, checking size, and handling noise. When you select a dc gear motor with care, the rest—wiring, powering, and controlling—becomes much easier.

Key Takeaways

- A 24V DC gear motor provides strong torque and steady speed, making it ideal for robotics applications.

- Select a power supply that matches the motor’s voltage and current requirements to ensure reliable operation.

- Use Pulse Width Modulation (PWM) for precise speed control and direction changes in your gear motor.

- Regular maintenance, including inspections and cleaning, helps extend the lifespan and performance of your motor.

- Choose the right type of gear motor based on your project’s specific needs, such as torque, speed, and space constraints.

Gear Motor 24VDC Overview

A gear motor 24vdc combines a DC motor with a gearbox. You use this type of motor in robotics because it gives you strong torque and steady speed. The compact design lets you fit the motor into tight spaces on your robot. You get high torque output, which is important for lifting or moving parts. The motor works efficiently, so your robot uses less power and runs longer. You can also customize the motor for special tasks.

Features and Benefits

When you choose a gear motor 24vdc for your robot, you gain several advantages:

- Compact design allows you to install the motor in small spaces.

- High torque output helps your robot handle demanding tasks.

- Efficient power usage means your robot performs better and saves energy.

- Versatility lets you customize the motor for your specific needs.

You also get higher power output compared to lower voltage motors. A 24v dc gear motor can deliver 40-50 watts or more. This makes it ideal for robots that need to lift or move heavy loads. The motor runs with less current than a 12V motor, so it generates less heat and lasts longer. The increased voltage gives you better torque, which is key for robotic arms and mobile robots.

Tip: Always check the torque and speed ratings before you pick a motor. Make sure the motor matches your robot’s needs.

INEED Product Options

INEED offers a wide range of gear motor 24vdc options for robotics projects. You can choose from:

- Small gear motors for compact robots

- Spur gear motors for simple, reliable motion

- Planetary gear motors for high precision and power

- Worm gear motors for quiet operation and self-locking features

- Brushless gear motors for long life and low maintenance

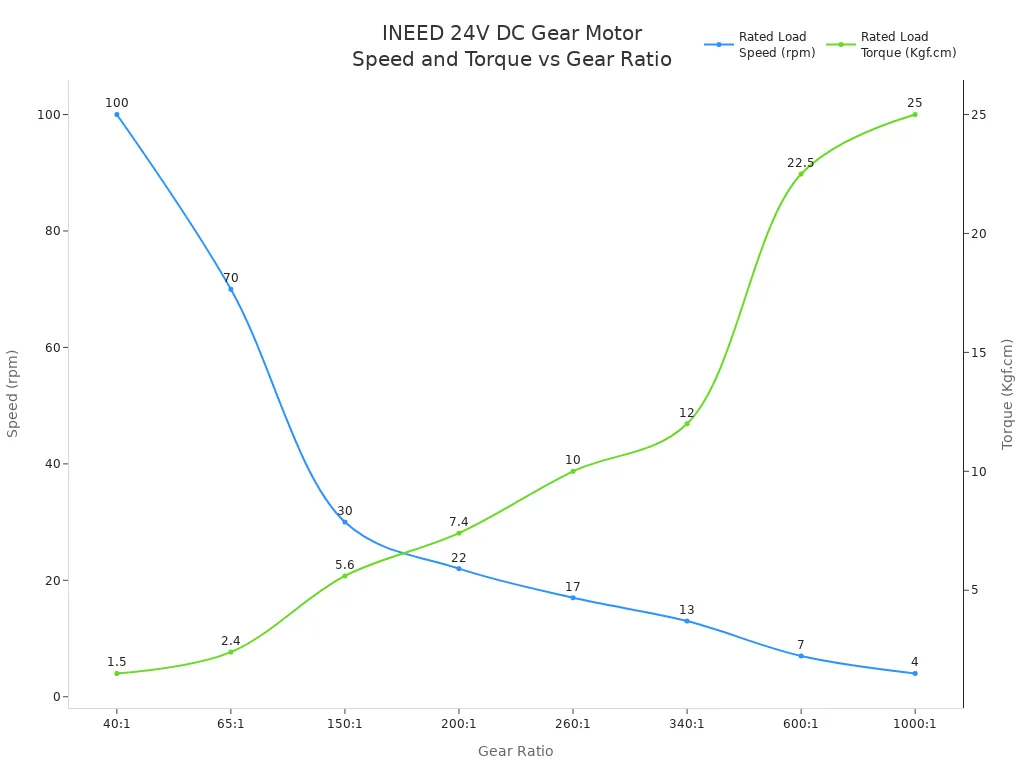

Here is a quick look at the typical torque and speed ranges for INEED’s 24V DC gear motors:

| Gear Ratio | No Load Speed (rpm) | Rated Load Speed (rpm) | Rated Load Torque (Kgf.cm) | Stall Torque (Kgf.cm) |

|---|---|---|---|---|

| 40:1 | 150 | 100 | 1.5 | 6.4 |

| 65:1 | 90 | 70 | 2.4 | 10 |

| 150:1 | 40 | 30 | 5.6 | 24 |

| 200:1 | 30 | 22 | 7.4 | 25 |

| 260:1 | 23 | 17 | 10 | 25 |

| 340:1 | 18 | 13 | 12 | 25 |

| 600:1 | 10 | 7 | 22.5 | N/A |

| 1000:1 | 6 | 4 | 25 | N/A |

You can use these motors in robotic arms, mobile robots, and automated systems. Each type gives you different benefits, so you can match the motor to your project.

Power Supply and Wiring

Selecting a Power Supply for 24V DC Gear Motor

Choosing the right power supply is essential for reliable operation of your gear motor 24vdc. You need to match the voltage and current ratings to your motor’s requirements. Most dc gear motors in robotics use a voltage range from 3V to 24V. For a 24V DC gear motor, you should select a power supply that delivers a steady 24V output.

| Voltage Range | Description |

|---|---|

| 3V | Minimum operating voltage for some DC gear motors |

| 24V | Maximum operating voltage for typical DC gear motors |

You must also consider the current rating. Motors draw more current when you demand higher torque. If your power supply cannot provide enough current, your motor may overheat or fail to start. Always check the stall current and rated current in the motor’s datasheet. For robotics projects, choose a power supply with a current rating at least 20% higher than the motor’s maximum draw.

Tip: Use a regulated power supply to avoid voltage spikes. Unstable power can damage your motor and control electronics.

When you plan your project, think about startup load. Motors often require more current when starting than during normal operation. If your power supply cannot handle this surge, your robot may experience resets or unreliable movement.

Gauge, for best results. Avoid using 14 gauge wire for long distances, as it cannot handle the load.

Safety Precautions

- Inspect your motor regularly for small issues. Early detection prevents bigger problems.

- Align the motor properly during setup. Misalignment causes vibration and damage.

- Select a motor that matches your task. Overloading leads to overheating and reduced efficiency.

- Keep the motor clean and dry. Moisture and dust reduce performance and lifespan.

- Monitor your power supply and use surge protectors. Voltage spikes can damage your motor.

- Check for loose or corroded connections. These disrupt power and cause failures.

- Watch voltage levels. Sudden drops may signal wiring problems.

- Be alert for signs of overheating, such as unusual smells or discoloration.

Common Wiring Mistakes and How to Avoid Them

- Unstable or inadequate power supply: Always verify connections and use a regulated power supply.

- Incorrect or improvised wiring: Follow the manufacturer’s diagrams and use properly rated cables.

- Voltage drop from long wire runs: Use thicker wires to maintain stable voltage.

Tip: Double-check all connections before powering up your robot. Careful wiring prevents costly mistakes and keeps your project running smoothly.

Control and Integration

Speed and Direction Control

You can control the speed and direction of your gear motor 24vdc with a few simple tools. The most common method for speed control is using Pulse Width Modulation (PWM). PWM lets you adjust how much power reaches the motor by switching the voltage on and off very quickly. You can use an Arduino or a dedicated PWM controller for this task. This method gives you precise speed control and keeps your motor cool.

Here is a table showing the benefits and considerations of using PWM for speed control:

| Benefits | Considerations |

|---|---|

| Efficient and precise speed control | Requires understanding of electronics and PWM |

| Minimal heat generation | May need extra components like controllers |

| Easy to adjust with microcontrollers | N/A |

To change the direction of your dc gear motor, you need a motor driver. The L298N driver works well for most robotics projects. You can also use drivers for brushless DC motors, PMDC brush motors, or stepper motors. The table below shows which motor types are compatible with direction control drivers:

| Motor Type | Compatibility |

|---|---|

| Brushless DC (BLDC) | Yes |

| PMDC Brush Motors | Yes |

| Stepper Motors | Yes |

You can connect your motor driver to an Arduino or other microcontroller. This setup lets you send commands to change speed and direction easily.

Tip: Always test your speed control setup with your robot’s load. Adjust the PWM signal to get the best performance.

Using Encoders and Feedback

Encoders help you get precise feedback from your gear motor 24vdc. You can track the position, speed, and direction of your motor in real time. This feedback is important for robots that need accurate movement, like robotic arms or mobile robots.

Here are some benefits of using encoders for speed control and feedback:

- You get precise location feedback for accurate adjustments.

- You receive real-time updates on position and speed.

- You can monitor and correct any errors in movement right away.

INEED offers customizable encoder options for your dc gear motor. You can choose different shaft shapes, voltage, output speed, torque, connectors, and gears. You can also add encoders to measure position, count, speed, or direction.

You can use controllers like Arduino, Raspberry Pi, or other microcontrollers to read encoder signals. INEED supports custom solutions, so you can match your motor and encoder setup to your project’s needs.

Note: Adding encoders improves your robot’s accuracy and makes speed control easier. You can adjust your robot’s movement based on real feedback.

Troubleshooting DC Gear Motor Issues

Common Mistakes

You may encounter several issues when working with a dc gear motor in robotics projects. Many problems come from simple mistakes. The table below shows common fault symptoms, possible causes, and solutions:

| Fault Phenomenon | Possible Causes | Solutions |

|---|---|---|

| Motor not starting | Unstable power supply, driver failure, wiring issues | Check power supply, inspect driver, verify wiring |

| Unstable or jittering speed | Controller settings, worn parts, excessive load | Adjust controller, inspect parts, confirm load |

| Motor overheating | Overload, poor cooling, high drive current | Reduce load, improve cooling, adjust current |

| Abnormal noise | Unbalanced rotor, debris, damaged bearings | Balance rotor, clean motor, lubricate bearings |

Other frequent mistakes include mismatched voltage, incorrect wiring, and ignoring startup current needs. Damaged gears often result from overloading or debris. Worn brushes and bearings can cause stalling or noise.

Tip: Always double-check your wiring and power supply before starting your robot. This simple step prevents many common problems.

Maintenance Tips

Regular maintenance helps your dc gear motor last longer and perform better. Follow these steps to keep your motor in top shape:

- Inspect brushes and commutator every 500–1000 hours. Clean them to prevent loss of performance.

- Listen for bearing noise and check for shaft play. Replace bearings if needed.

- Measure insulation resistance with a megohmmeter. Dry or repair if resistance drops below safe levels.

- Clean vents and cooling paths to prevent overheating.

- Monitor motor temperature during operation. Use thermal sensors for safety.

- Tighten all electrical connections to avoid arcing and voltage drops.

- Align motor and load correctly to reduce wear.

- Lubricate bearings as recommended by the manufacturer.

- Use proper protection devices for overload and short circuits.

- Keep detailed maintenance records to spot recurring issues.

INEED supports you with expert advice and technical help. You can contact their team for troubleshooting, maintenance guidance, and custom solutions. Regular inspections, cleaning, and proper alignment will help you avoid most failures. Quality motors from INEED reduce the risk of breakdowns and keep your robotics projects running smoothly.

Note: Reliable support and high-quality products make troubleshooting easier. Choose trusted brands like INEED for peace of mind.

To integrate a 24V DC gear motor into your robotics project, follow these steps: connect the hall and power lines correctly, set up the driver ports, and adjust speed as needed. Choose high-quality gear motors like those from INEED for custom design, expert advice, and reliable performance. Always label and secure wires, use proper connectors, and keep cables away from moving parts. If you need custom torque, speed, or dimensions, INEED’s team can help tailor solutions to your project.

FAQ

How do you choose the right 24V DC gear motor for your robot?

You should check your robot’s required torque, speed, and size. Match these needs to the motor’s specifications. INEED offers many options, so you can find a motor that fits your project.

Can you run a 24V DC gear motor with a lower voltage?

Yes, you can run the motor at a lower voltage. The motor will spin slower and produce less torque. Always check the minimum voltage in the datasheet to avoid stalling.

What is the difference between a spur, planetary, and worm gear motor?

| Type | Key Feature | Best Use |

|---|---|---|

| Spur | Simple, reliable | Basic motion |

| Planetary | High torque, precise | Heavy loads, robotics |

| Worm | Quiet, self-locking | Holding positions |

Tip: Choose the gear type based on your robot’s needs.

How often should you maintain your DC gear motor?

You should inspect your motor every few months. Clean dust, check for loose wires, and listen for noise. Regular care helps your motor last longer and work better.

Can you customize a 24V DC gear motor for special projects?

Yes! INEED can customize shaft shape, speed, torque, and add encoders. You just need to share your requirements with their team. Custom motors help you solve unique robotics challenges.

See Also

Utilizing 3V DC Motors Across Five Different Devices

Choosing the Ideal 3 Volt DC Motor for Your Needs

Guidelines for Choosing the Perfect Rotary Motor for Industry