You often find the N20 gear motor at the heart of today’s compact electronic devices. This motor combines a small DC motor with an integrated gearbox, which allows for high torque in limited spaces. You see its impact in modern electronics, such as robotics, camera gimbals, and smart home devices. The global market for these motors continues to grow, as shown below:

| Year | Market Size (USD Billion) | Growth Rate (CAGR) |

|---|---|---|

| 2023 | 24.38 | N/A |

| 2024 | 25.63 | N/A |

| 2030 | 38.38 | 7.0% |

INEED stands out as a leader in micro motor manufacturing. You benefit from their focus on customization, strict quality control, and solutions for industries like healthcare, automation, and telecommunications.

Key Takeaways

When selecting an N20 gear motor, consider factors like size, torque, noise level, and application requirements to ensure optimal performance.

N20 gear motors combine a small DC motor with a gearbox, providing high torque in compact spaces, ideal for robotics and smart devices.

Three main types of N20 gear motors are available: spur, planetary, and worm gear motors, each suited for different applications and offering unique benefits.

Customization options from INEED allow you to tailor motors to specific needs, including voltage, gear ratios, and output shafts, ensuring the right fit for your project.

N20 gear motors are known for their compact size, high torque, and reliability, making them perfect for use in medical devices, consumer electronics, and automation.

N20 Gear Motor Overview

Definition

You can think of an N20 gear motor as a small but powerful device that combines a DC motor with a built-in gearbox. This design allows you to get more torque at lower speeds, which is perfect for applications where space is limited but strength is needed.

Why is it called N20 DC Motor ?

The N20 gear motor uses a compact DC motor paired with a spur gear reducer.

The gearbox reduces the speed of the output shaft and increases the torque.

The term “N20” refers to the motor’s size, which is typically 15mm long, 12mm wide, and 10mm high.

This type of motor is popular in robotics, smart devices, and precision instruments because it converts high-speed, low-torque motion into low-speed, high-torque output.

Size and Origin

You will notice that the N20 gear motor stands out for its small size and lightweight build. This makes it easy to fit into tight spaces inside modern devices.

The N20 gear motor traces its roots to the demand for compact, efficient motors in electronics and automation. INEED, founded in 2011 in Hong Kong, has become a leader in this field. You benefit from their expertise in high-precision small gear motors and brushless DC motors. INEED operates advanced factories in Shenzhen and Huizhou, which helps them deliver consistent quality and meet the needs of clients worldwide.

Core Function

You use an N20 gear motor when you need reliable motion control in a small package. The core function of this motor is to convert electrical energy into mechanical movement, while the integrated gearbox adjusts the speed and torque to match your application.

- The gearbox allows you to achieve high torque at low speeds, which is essential for tasks like moving robotic arms or adjusting camera lenses.

- The motor’s compact size lets you install it in devices where space is limited.

- Every N20 gear motor from INEED undergoes strict quality checks to ensure it meets industry standards.

Note: INEED’s N20 gear motors comply with important certifications, including CE, RoHS, and REACH. They also pass rigorous tests like the ASTM B117 salt spray resistance and MIL-STD-810 vibration endurance. This means you can trust these motors for both safety and durability.

INEED’s commitment to research and development, along with their focus on continuous improvement, ensures that you receive motors that are both reliable and efficient. You can rely on their products for a wide range of uses, from medical devices to smart home technology.

Types

When you explore N20 gear motor options, you will find three main types: spur gear motors, planetary gear motors, and worm gear motors. Each type offers unique features and benefits for different applications. INEED provides a full range of these motors, allowing you to choose the best fit for your project. You can also request custom designs, gear ratios, and output shafts to match your specific needs.

Spur Gear Motor

Spur gear motors use straight-cut gears to transfer motion. You will notice their simple design and reliable performance. These motors are easy to maintain and cost-effective, making them a popular choice for many devices.

Here is a comparison table to help you understand how spur gear N20 motors stand out:

| Characteristic | Spur Gear N20 Motors | Other Gear Motors |

|---|---|---|

| Efficiency | High | Variable (lower in worm) |

| Durability | High | Variable |

| Design Complexity | Simple | More complex (planetary) |

| Torque Consistency | Consistent | Variable |

| Maintenance Ease | Easy | Often complex |

| Cost | Affordable | Higher (especially planetary) |

You benefit from these features:

- Consistent torque output

- Low energy waste

- Affordable and easy to maintain

- Versatile across various applications

INEED’s spur gear motors come in different sizes and configurations. You can select open-frame or closed-frame designs, choose between steel or brass gears, and even add encoders for position feedback. If you need a special output shaft or a unique gear ratio, INEED can customize the motor for you.

Tip: Spur gear N20 motors work well in robotics, automation, and consumer electronics where you need reliable and efficient motion control.

DC Motor Type: Brushed Motor

Output Speed (No Load): 20 rpm~2000 rpm (Customized )

Gearhead Type: Spur

Gear Ratio: 1:5 ~1:1000, Total: 15 gear ratios Rated Voltage: 2.5 VDC~12VDC

No Load Current: 40mA (Customized )

Maximum Stall Torque: 9000g.cm (Customized )

Core Construction: Metal

Standards Met: RoHS Compliant

DC Motor Type: Brushed Motor

Output Speed (No Load): 54 rpm

Gearhead Type: Spur

Gear Ratio: 1:5 ~1:380, Total: 13 gear ratios (Customized ) Rated Voltage: 2.5 VDC~12VDC

No Load Current: 40mA (Customized )

Maximum Stall Torque: 4200g.cm (Customized )

Core Construction: Metal

Standards Met: RoHS Compliant

DC Motor Type: Brushed Motor

Output Speed (No Load): 12rpm~1500 rpm (Customized )

Gearhead Type: Spur

Gear Ratio: 1:3 ~1:750, Total: 15 gear ratios Rated Voltage: 2.5 VDC~12VDC

No Load Current: 60mA (Customized )

Maximum Stall Torque: 8000g.cm (Customized )

Core Construction: Metal

Standards Met: RoHS Compliant

Planetary Gear Motor

Planetary gear motors use a central sun gear surrounded by planet gears. This design gives you higher torque and better load distribution. You will find these motors in applications that demand precision and power in a compact space.

You often see planetary N20 gear motors in:

- Robotics: They provide high torque and precise control for robot wheels and arms.

- Automation: These motors power conveyor systems and assembly lines.

- Camera Gimbals: They deliver stable video with low noise and vibration.

- DIY Projects: Their versatility and affordability make them ideal for custom builds.

INEED offers planetary gear motors with a wide range of gear ratios and output speeds. You can choose the material, voltage, and even add encoders for feedback. If your project requires a special shaft or mounting, INEED’s engineers can design a custom solution for you.

DC Motor Type: Brushed Motor

Output Speed (No Load): 65 rpm~165 rpm (Customized )

Gearhead Type: Planetary

Gear Ratio: 1:120 Rated Voltage: 1.5VDC~12VDC

No Load Current: 50mA (Customized )

Maximum Stall Torque: 2880g.cm (Customized )

Core Construction: Metal

Standards Met: RoHS Compliant

Note: Planetary gear motors are known for their high efficiency and smooth operation. You get more torque in a smaller package compared to other gear types.

Worm Gear Motor

Worm gear motors use a worm (screw) and a gear wheel to transfer motion at a right angle. You will notice their compact size and self-locking ability, which prevents back-driving. These motors are perfect for applications where you need to hold a position without extra power.

Here is a table comparing the efficiency of different gear types:

| Gear Type | Efficiency |

|---|---|

| Worm Gear | 30% to 60% |

| Planetary Gear | High |

| Spur Gear | High |

Worm gear N20 motors have some unique advantages:

- Self-locking feature for safety

- High torque output in a small space

- Quiet and smooth operation

You can use worm gear motors in devices that need precise movement and holding force, such as medical equipment or security systems. INEED allows you to customize the voltage, shaft shape, and even the gear material to fit your requirements.

Tip: Worm gear motors are ideal when you need motion at a 90-degree angle or require a motor that can hold its position without slipping.

DC Motor Type: Brushed Motor

Output Speed (No Load): 10 rpm~200 rpm(Customized )

Gearhead Type: Worm

Gear Ratio: 1:59~1:1168 Rated Voltage: 6VDC, 12VDC

No Load Current: 35mA (Customized )

Maximum Stall Torque: 16800g.cm (Customized )

Core Construction: Metal

Standards Met: RoHS Compliant

Customization Options from INEED

INEED stands out by offering a wide variety of customization options for all N20 gear motor types. You can request:

- Custom specifications for voltage, speed, and torque

- Special output shafts and gear ratios

- Encoders for position feedback

- Unique packaging or branding for large orders

You can also get samples for testing before placing a bulk order. INEED’s engineers will work with you to design the perfect motor for your application.

| Customization Option | Details |

|---|---|

| Custom specifications | Available for all models |

| Samples | Provided for testing |

| Minimum Order Quantity | 2000 pcs (smaller orders possible initially) |

| Product Suitability | Recommendations based on your requirements |

| Branding/Packaging | Available for large orders |

Note: INEED’s strong R&D team and advanced manufacturing ensure you receive high-quality, reliable motors tailored to your needs.

Specifications

Technical Data

When you select a motor for your project, you need to know its technical specifications. The N20 gear motor stands out for its balance of size, power, and versatility. Here are the main technical details you should consider:

- Size: 10 mm × 12 mm × 15 mm (motor body)

- Voltage: Operates between 3V and 12V

- Torque: Delivers high torque at low speeds, suitable for precise control

- Speed: Available in a wide range of output speeds, depending on the gear ratio

- Operating Temperature: Functions well from -10°C to +50°C

Tip: The wide operating temperature range means you can use this motor in both indoor and outdoor environments.

You can rely on these specifications to match the N20 gear motor to your application, whether you build a robot, a medical device, or a smart home gadget.

Comparisons

You may wonder how the N20 gear motor compares to other micro gear motors, such as the N10. The following tables help you see the differences in performance and best uses.

| Motor Type | Size (mm) | Best Applications |

|---|---|---|

| N20 Motor | 10 x 12 x 15 | Robotics, CNC machines, medical pumps, industrial automation |

| N10 Motor | 8 x 10 x 12 | Small drones, camera gimbals, toy cars, wearable devices |

You also want to compare their torque and current characteristics:

| Motor Type | Stall Current (amps) | Torque Output | Comments |

|---|---|---|---|

| N10 | 1.0+ | More powerful than most N20 | Suitable for 2.0 amp ESCs |

| N20 | 2.0+ | Hard to stall with common drive systems | Often used in lighter bots |

| Cheap N20 | ~0.25 | Struggles to move 150g | Not suitable for pushing matches |

| Decent N20 | ~0.45 | Moves itself well | Not competitive in pushing |

| Good N20 | ~0.90 | Authority with 150g bots | Occasionally used in 1lb bots |

You see that the N20 gear motor offers a great mix of size and power. It works well in many applications where you need reliable torque and compact design. The N10 motor is smaller and fits best in lightweight or space-limited devices.

Advantages

Compactness

You will notice that the N20 gear motor stands out for its small size. This compact design lets you fit the motor into tight spaces where larger motors cannot go. Devices like medical pumps, smart locks, and miniature robots all benefit from this feature. INEED uses advanced materials and precise engineering to keep the motor lightweight without losing strength. You can choose custom shapes or shaft designs to match your device perfectly. This flexibility helps you create smaller, more efficient products.

High Torque

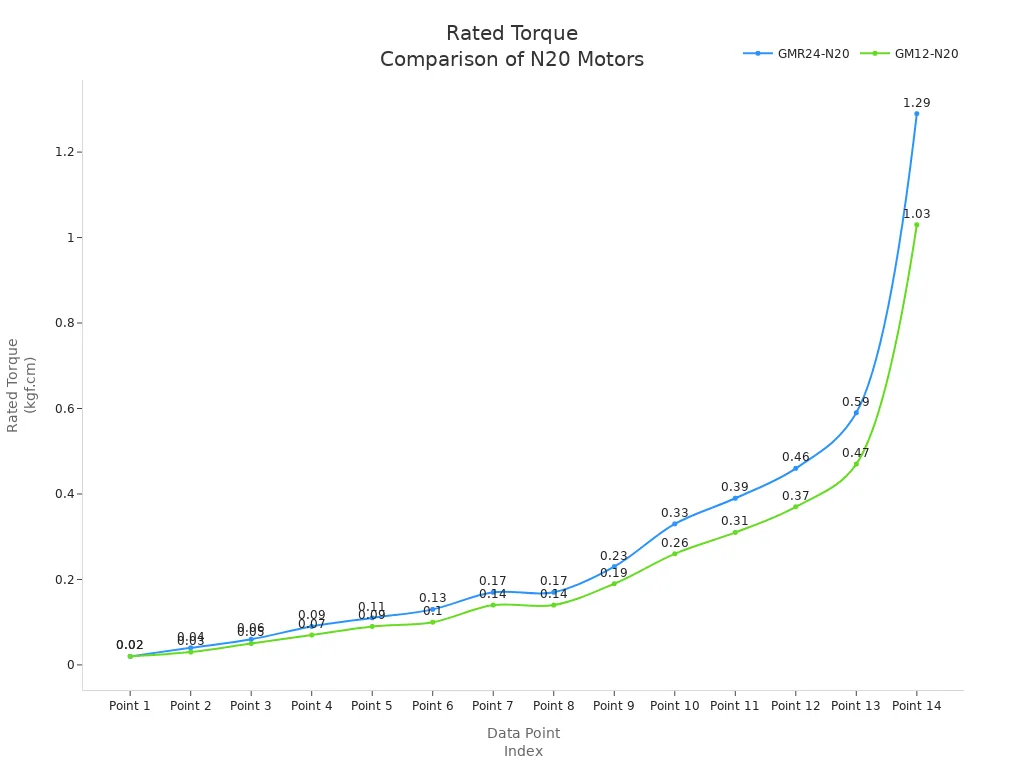

You get impressive torque from the N20 gear motor, even though it is small. This means you can move heavier loads or achieve precise control in your projects. The following table shows how the rated torque compares across different models:

| Motor Model | Rated Torque (kgf.cm) | Max Allowable Moment Torque (kgf.cm) |

|---|---|---|

| GMR24-N20 | 0.02, 0.04, 0.06, 0.09, 0.11, 0.13, 0.17, 0.17, 0.23, 0.33, 0.39, 0.46, 0.59, 1.29 | 1.5 |

| GM12-N20 | 0.02, 0.03, 0.05, 0.07, 0.09, 0.10, 0.14, 0.14, 0.19, 0.26, 0.31, 0.37, 0.47, 1.03 | 1.5 |

| N20 High Torque | 0.045 (NM) | N/A |

You can see that these motors deliver a range of torque values, making them suitable for many tasks. INEED offers custom gear ratios, so you can select the right balance of speed and torque for your needs.

Reliability

You want a motor that works well over time. INEED ensures reliability by testing every unit for performance and durability. The company checks for noise, vibration, and temperature stability. Here are some of the tests performed:

- Behaviour over time

- Component assessment

- Failure analysis (electrical and mechanical)

- Measurement of vibration, torque, speed, and temperature

- Grease and lubricant analysis

INEED’s quality control process includes advanced inspections at every stage. You benefit from features like overload protection, low noise, and high energy efficiency. The table below shows typical noise levels for different models:

| Model Type | Noise Level (dB) |

|---|---|

| Base Model | 55 |

| Advanced Model | 47 |

| Pro Model | 38.5 |

You can expect quiet operation, which is important for medical devices and smart home products. INEED also offers motors with high energy efficiency ratings, helping you save power in your designs.

Note: INEED’s customization options let you choose the right motor for your application, whether you need special gear ratios, output shafts, or encoders.

Applications

Industry Uses

You will find the N20 gear motor in many devices across both consumer and industrial markets. Its compact size and high torque make it a favorite for engineers and designers. The table below shows some of the most common applications:

| Application Type | Examples |

|---|---|

| Consumer Applications | High-End Mobile Phones, Personal Digital Devices, Beauty Equipment, Mascara Cream, Personal Care, Home Appliance |

| Industrial Applications | Medical Devices, Security Equipment, Industrial Tools |

In robotics, you often see this motor in small robotic arms, drones, and DIY robotics kits. Its precise control and small footprint help you build complex machines in tight spaces. In the medical field, you will notice it in portable equipment like infusion pumps and diagnostic tools. These devices need reliable, quiet, and efficient motors to function safely.

Selection Tips

When you choose a gear motor for your project, you should match the motor’s features to your application’s needs. Consider the following factors:

| Feature | Description |

|---|---|

| Compact Size | Fits easily into space-constrained projects. |

| High Torque | Handles tasks that need significant force, such as robotics or automation. |

| Low Noise and Vibration | Important for medical devices and quiet environments. |

| Versatile Applications | Works well in robotics, automation, and DIY projects. |

| Durable Construction | All-metal gears ensure long-lasting performance. |

You should also look for efficient design, low power consumption, and a wide range of gear ratios. These features help you balance speed and torque for your specific task. If you need quiet operation, select a model designed for low noise. For precise movement, choose a motor with excellent speed control.

INEED supports you with expert advice and customization services. Their team can help you select the right motor, adjust specifications, and even design custom shafts or gear ratios. You can request samples for testing, and every product meets strict quality standards. This support ensures your project runs smoothly from start to finish.

Tip: Always define your application’s requirements before selecting a motor. INEED’s engineers can guide you through the process and provide tailored solutions.

N20 gear motors give you high torque, compact size, and precise control. You can see how they compare to traditional motors in the table below:

| Feature | N20 DC Gear Motors | Traditional DC Motors |

|---|---|---|

| Torque Output | High torque at low speeds | Lower torque efficiency |

| Size | Compact and lightweight | Larger and heavier |

| Efficiency | High energy efficiency | Lower energy efficiency |

| Control | Precise speed control | Less precise control |

INEED offers you reliable motors with many customization options, such as different voltages, shaft types, and gear materials. You should review your technical needs and explore INEED’s wide product range for a solution that fits your project

FAQ

What Is The Use of N20 Gear Motor?

The N20 motor is proving to be well suited for compact IIOT(Industrial Internet of Things) applications such as electric locks, webcam panning mechanisms and other similar actuator products that require excellent torque within a limited size and reduced weight.

What size is the N20 gearmotor?

N20 DC motor size 15 x 12 x 10 mm. Depending on the speed ratio, the gearbox length is available in two options: 9mm and 11mm. The N20 gearmotor comes in various sizes, with different shaft lengths and shapes that can be customized according to specific requirements.

What Is The Difference Between N20 and N10 Gear Motors?

The N10 motor is smaller and lighter than the N20 motor. Both types of DC gear motors are available to us. In addition, it is important to mention that torque and stall current exhibit a near linear relationship in these motors, which means that as you increase the torque requirement, the current will also increase proportionally.

What is the difference between an N20 gear motor and a regular DC motor?

You get higher torque and lower speed with an N20 gear motor because it has an integrated gearbox. A regular DC motor runs faster but cannot move heavy loads as easily.

How do you choose the right N20 gear motor for your project?

You should define your application, check the required torque and speed, and measure available space. INEED’s team can help you select the best model and customize features for your needs.

Can you request custom specifications for N20 gear motors from INEED?

Yes, you can ask for custom voltage, gear ratios, output shafts, and encoders. INEED offers samples for testing and supports you with expert advice.

What industries use N20 gear motors most often?

You see N20 gear motors in robotics, medical devices, smart home products, and consumer electronics. Their compact size and high torque make them ideal for these fields.

Tip: You can contact INEED for technical support or to request a sample before placing a bulk order.